MSR Assemblies

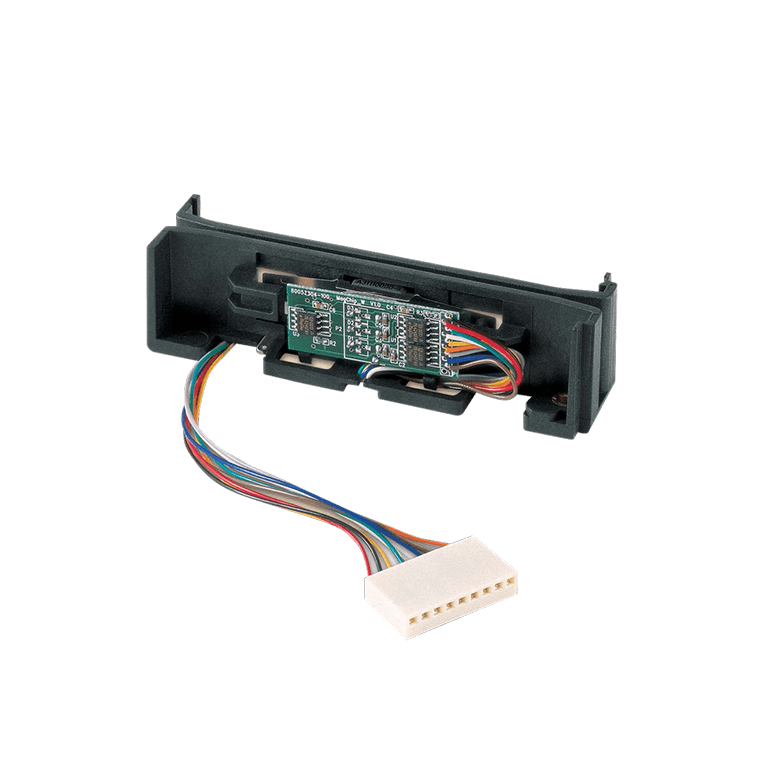

Customizable Magstripe Rail

MSR Assemblies

Using ID TECH's low-power TriMagChip™ technology, the 90mm rail reads up to three tracks of card data with a single swipe in either direction. The dual head option places a magstripe read head on either side of the card slot, allowing users to swipe their card in any orientation.

- Provides excellent data jitter, media glitch, and dropout immunity, with less than one error in 100,000 bits.

- Fully customizable, configurable data format.

- Extremely durable with an operating life of over 1,000,000 card swipes.

- Available in single head and dual head options.

Download Datasheet

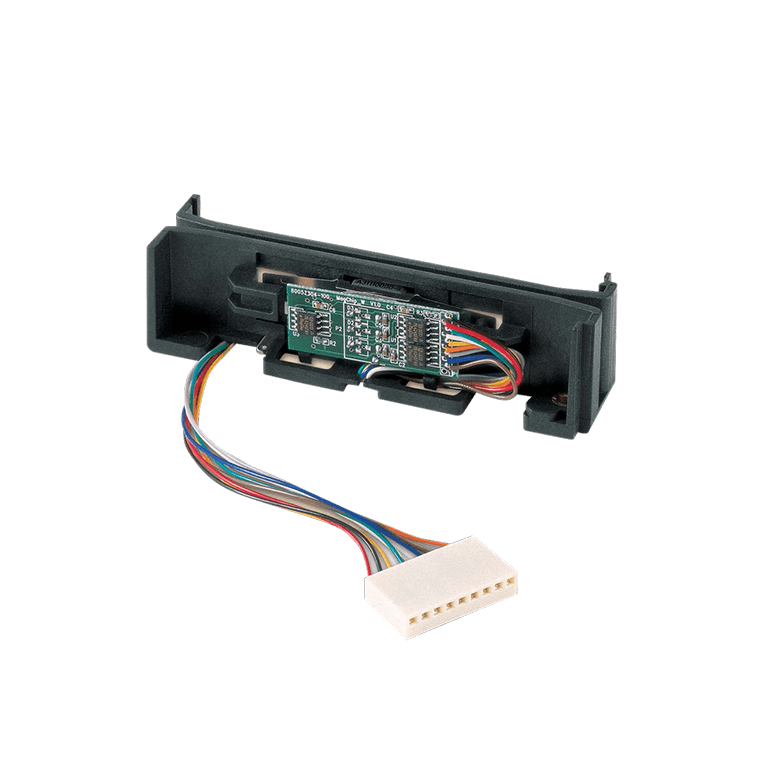

MSR Assemblies

Using ID TECH's low-power TriMagChip™ technology, the 90mm rail reads up to three tracks of card data with a single swipe in either direction. The dual head option places a magstripe read head on either side of the card slot, allowing users to swipe their card in any orientation.

- Provides excellent data jitter, media glitch, and dropout immunity, with less than one error in 100,000 bits.

- Fully customizable, configurable data format.

- Extremely durable with an operating life of over 1,000,000 card swipes.

- Available in single head and dual head options.

Download Datasheet

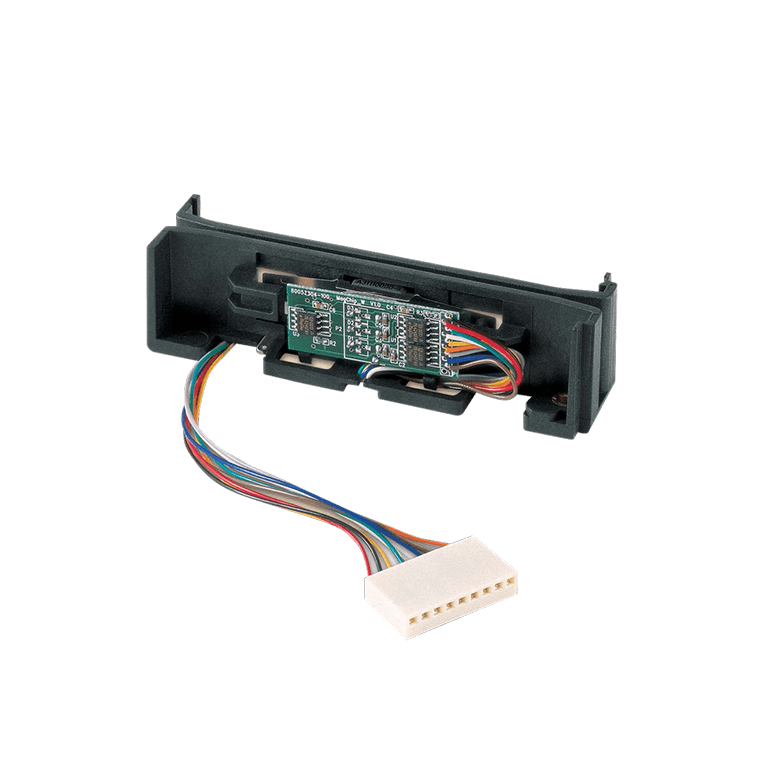

Power

Operation from 2.7 to 5.5 VDC, Ground 0 VDC (GND)

Operating Temperatures

-40°C to 70°C (-40°F to 158°F)

Storage Temperatures

-40°C to 85°C (-40°F to 185°F)

Dimensions

90 mm x 24 mm x 24 mm

Key Features

- Multiple Configurations Available

- Fully Customizable

- USB-HID, USB-KB, RS232, Keyboard Wedge, TTL Interfaces

- Configurable data format

- Single or Dual Read Head Options

- Legendary ID TECH Reliability

USB (IDBB-6642LRB)

LED, beep tone

1GHz, X1500 Processor

Sense mode, Continuous mode, Level mode, Pulse mode

60 frames per second

PDF417, QR Code, Data Matrix, AZTEC, CSC, Maxicode, Micro QR, Micro PDF417, GM , Code One, etc.

Tell Me More

"*" indicates required fields