RESOURCES

Datasheets

ID TECH offers a range of payment devices - from payment terminals, to mobile payments, OEM devices, POS hardware, and touchscreen displays. View our product datasheets to learn more about each product. Search by product type, solution type, or both.

2D Scan FX200

A multi-purpose fixed-mount 2D barcode reader. Compact and reliable. Plug-and play design.

AP6800

An all-in-one unattended payment terminal with Android 13 operating system. PCI 6.X SRED certified.

Augusta

A compact and secure EMV chip and magnetic stripe card reader, ideal for retail and hospitality.

EconoScan III

Lightweight, short-range CCD barcode scanner that is designed to deliver high-end performance.

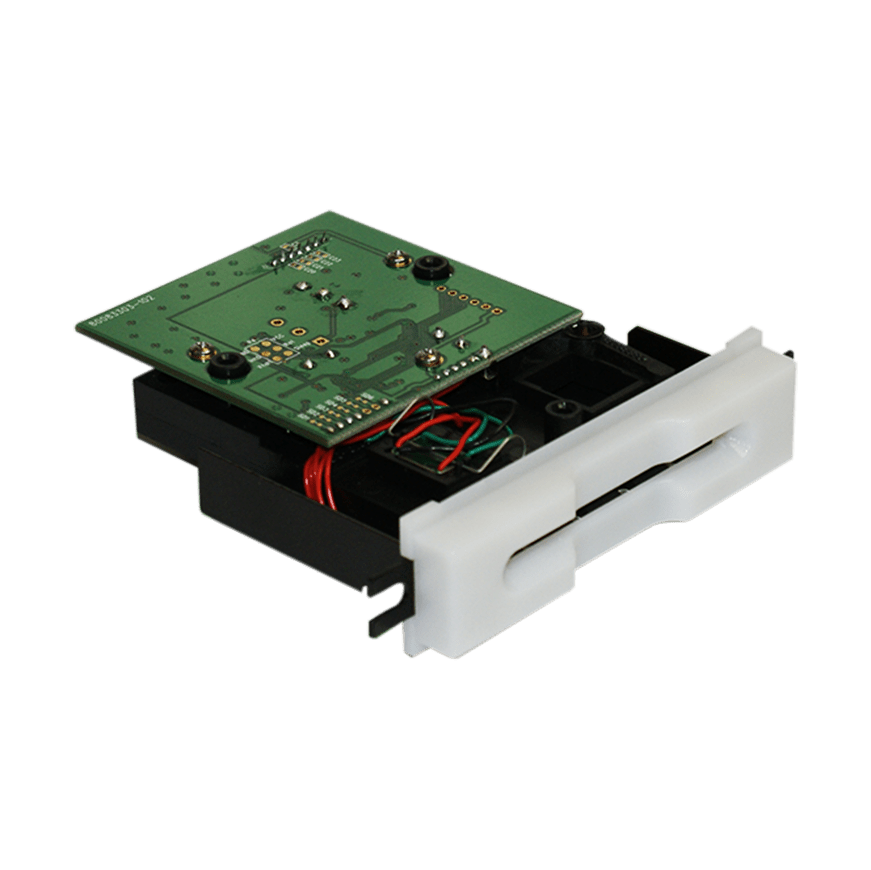

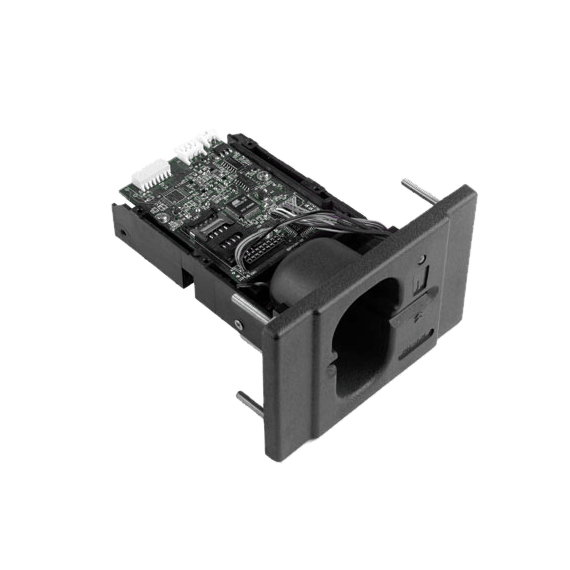

Gaming Reader

A manually-operated, partial insert reader supporting single, dual, or triple track magnetic heads.

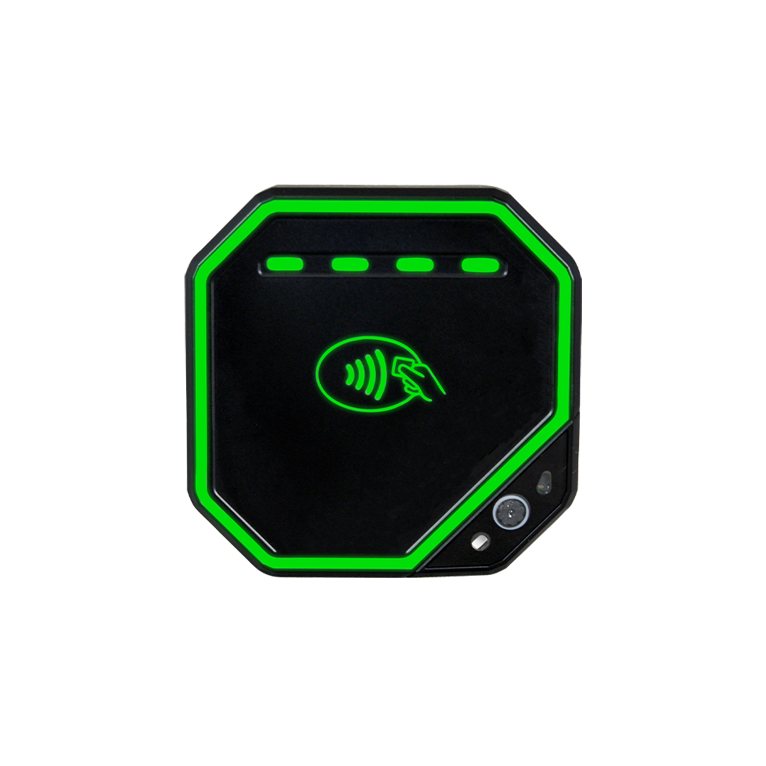

Kiosk III

A robust, compact NFC reader that supports contactless cards, mobile payments, and loyalty programs.

Kiosk IV

An outdoor NFC payment device ready for taking contactless payments. Ideal for parking and transit.

Kiosk V

Our newest contactless card reader supporting mobile payments and loyalty programs. EMV certified.

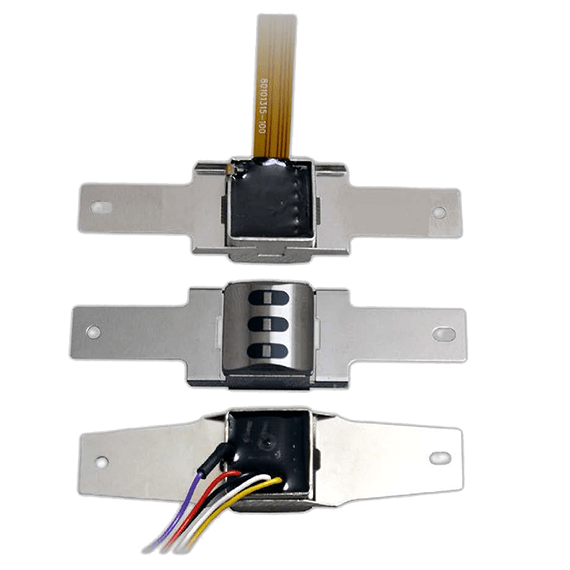

MiniMag Duo

A dual-headed magstripe reader that reads cards regardless of the orientation of the magnetic strip.

MiniMag II

A card reader that can read up to three tracks of magstripe data regardless of swipe direction.

Omni

Combo magstripe and barcode reader that can scan barcodes printed on paper, card stock, or plastic.

PiP

Designed for redeeming loyalty rewards & accessing events. Supports Apple VAS, Google Pay & Mifare.

PiP OEM

OEM NFC solution for loyalty programs including Apple VAS & Google Pay Smart Tap

SecureKey M130

An encrypted keypad with a magstripe reader that offers retailers a complete security solution.

SecureMag

A PCI-compliant magnetic stripe card reader that encrypts data complying with PCI-DSS requirements.

Spectrum Air

A weather-resistant dual-headed magnetic stripe insert reader ready for outdoor environments.

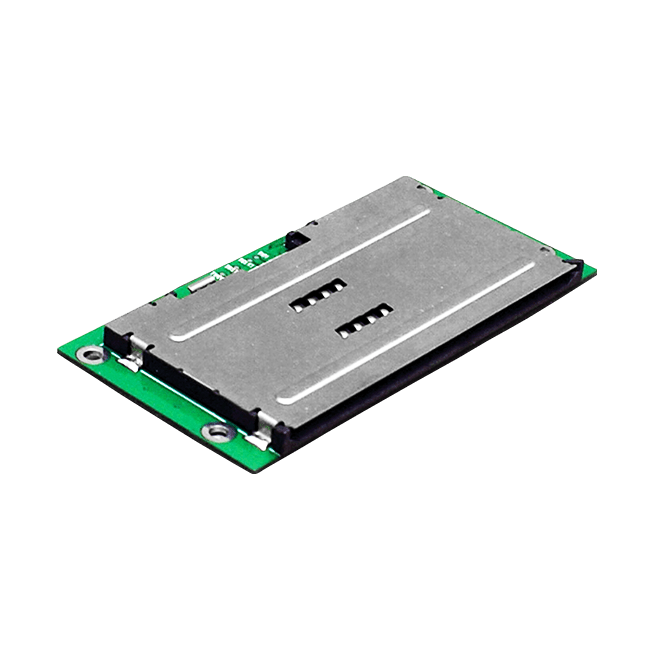

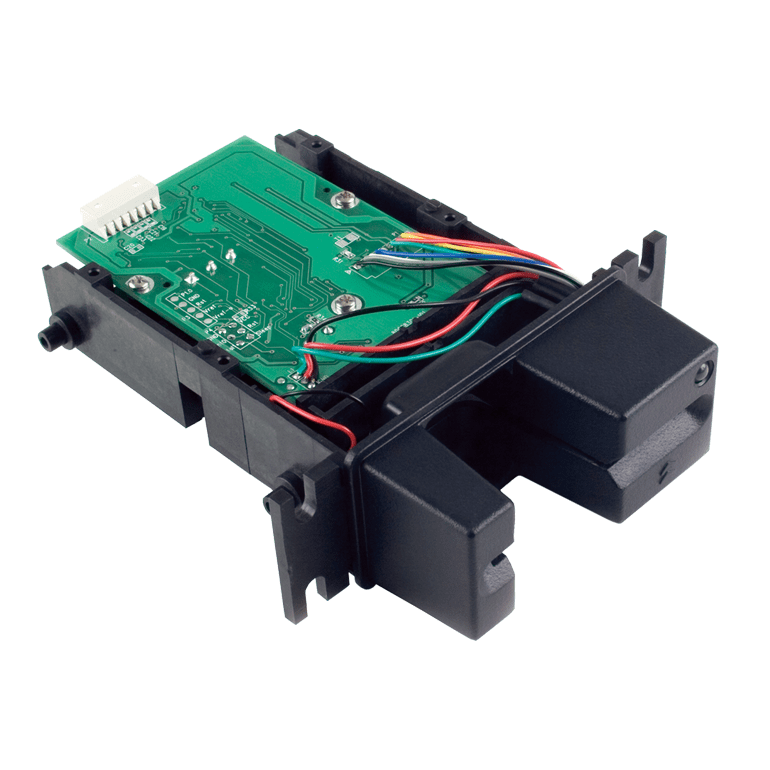

Spectrum III Hybrid

A hybrid insert card reader that can read both magnetic stripe cards and smart cards.

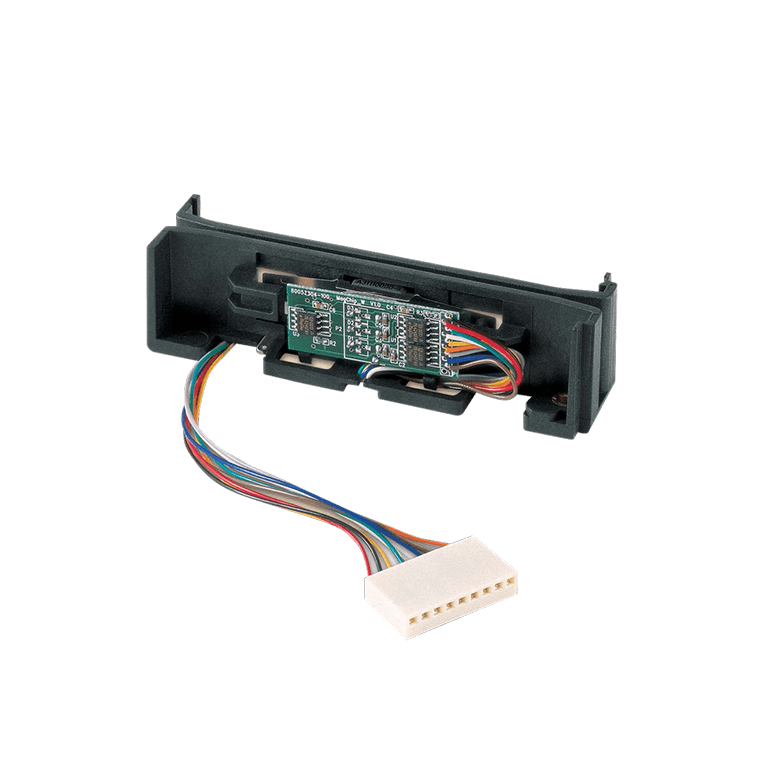

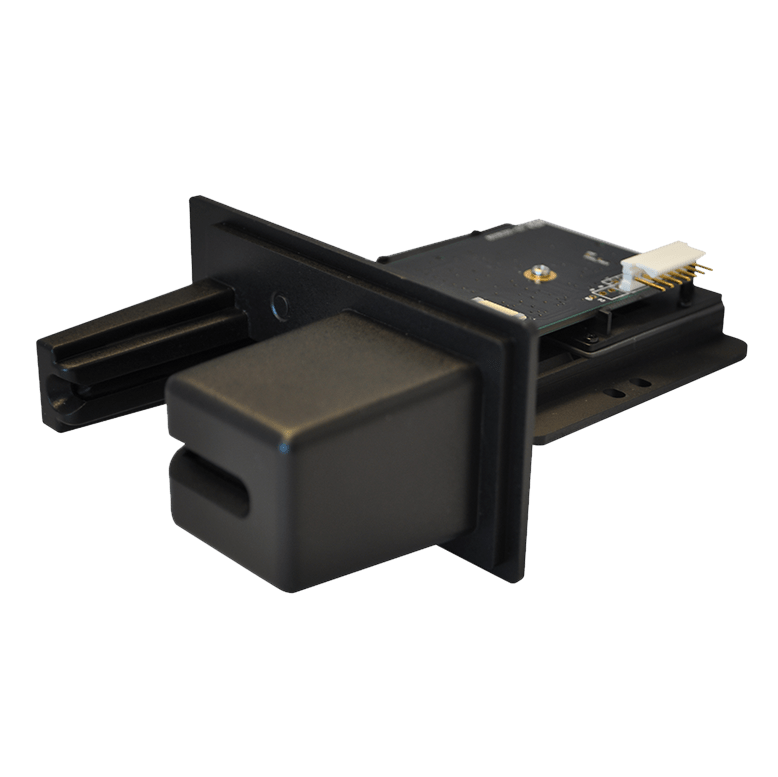

Spectrum III MOIR

A Magstripe-Only Insert Reader that can read and encrypt up to three tracks of magnetic stripe data.

SREDKey 2

A PCI PTS 6.X encrypted keypad that is ideal for P2PE solutions in back-office environments.

ValueScan III

A mid-range 1D barcode scanner with an auto-sensing feature and a scanning range up to 12 inches.

VP3300

An all-in-one mobile payment device to accept magstripe, chip & NFC payments on the phone/tablet.

VP3300 OEM

3-in-1 OEM solution for magstripe, EMV contact, and EMV contactless integration.

VP3350

Robust wireless device ready for all types of card/mobile payments. Perfect for business on-the-go.

VP3350 with Stand

Robust wireless device ready for all types of card/mobile payments. Perfect for business on-the-go. Stand included.

VP3600

A mobile chip & PIN payment terminal for smartphones/tablets that also supports magstripe and NFC.

VP5300

A ruggedized unattended insert card reader that accepts magstripe, chip, NFC & mobile payments.

VP5300 Antenna

Ready to be bundled with a VP5300 card reader for contactless card/mobile payments.

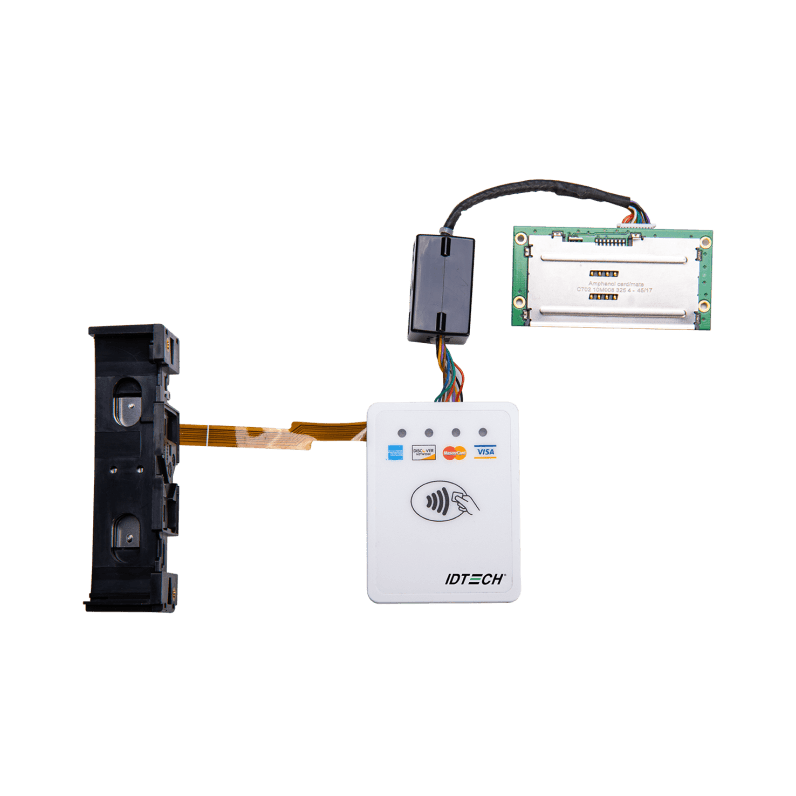

VP5300 Bundle with SmartPIN L100

Our unattended payment device bundle featuring the VP5300, VP5300 NFC Antenna, and SmartPIN L100.

VP5300 Bundle with SmartPIN L80

An unattended payment solution consisting of the VP5300, VP5300 NFC Antenna, and SmartPIN L80.

VP5300M

The world’s first PCI SRED certified motorized insert reader that accepts MSR, EMV, & NFC payments.

VP5300M Bundle

Includes our VP5300M, VP5300 NFC Antenna, and SmartPIN L100 products for unattended payment environments.

VP5300M Bundle with SmartPIN L80

Our motorized insert reader bundle solution including VP5300M, VP5300 NFC Antenna, and SmartPIN L80.

VP6300

An unattended payment device designed for vending machines. Ready to take card and mobile payments.

VP6800

A PCI 5.X certified unattended smart payment device with 4.3″ interactive touchscreen and camera.

VP6825

Unattended payment terminal supporting contactless payments & QR codes for vending, parking & more.

VP7200

Smart NFC reader with QR code scanner that can host payment applications and drive an external LCD.

VP8300

An all-in-one payment solution for EMV chip, magnetic stripe, and contactless payments.